Custom Printed Rollstock

Custom Printed Rollstock is what you need for creating pouches on your own automated form, fill, and seal line. It’s most commonly used to form fin seal bags, lay flat pouches, sachets and stick packs.

Bring your packaging to life with the following features:

Custom Printing

Custom Sizing

Custom Materials

Custom External Finish

Tear Notch

Window Knockouts

Metallic Effects

Custom Roll Orientation

Custom Printing

Using the world’s most advanced print technologies, you have full control on exactly how your pouches are printed from vector to photographic art elements.

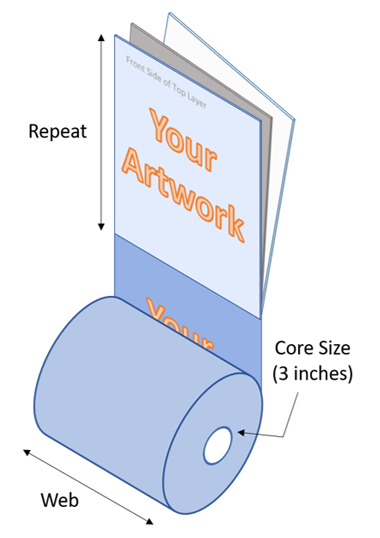

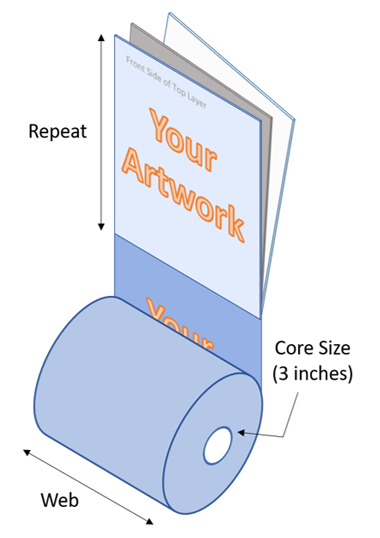

Custom Sizing

Fully Customizable Web and Repeat – no size is off the table.

Custom Materials

Choose from a variety of high barrier films to protect your product such as PET, BOPP, Metalized PET, Aluminum Foil, and Kraft Paper

Custom External Finish

Choose from gloss, matte, or soft touch matte to complete your look.

Tear Notch

Provide your customers an easy way to open their packaging.

Window Knockouts

Give consumers a glimpse of your product by incorporating either clear or frosted windows throughout your design.

Metallic Effects

Make your graphics pop with metallic shine effects on your bag, anywhere and in any color.

Custom Roll Orientation

Choose from any of the 8 outside or inside wound roll configurations to ensure your final, filled pouches are exactly how you want them.

Quality Assurance

Every pouch goes through a strict Quality Control process, ensuring the highest quality on every run.

Certified Production

Our manufacturing facilities are BRC-GS certified, the highest level for Food Packaging Safety.

High-Barrier Films

We only use films and materials that are recognized by the FDA as food contact safe. All inks are water based.

A printed roll of laminated film typically goes through either a vertical (left) or horizontal (right) Form, Fill, & Sealing (FFS) line to fill your product into a bag that is simultaneously being formed and heat sealed shut.

*Digitally printed custom rollstock ships out in about 7 business days and can be delivered to most destinations around the world within 2-3 weeks. Rotogravure printing – the kind of print that uses printing cylinders – requires longer production timelines and is not an economical option for most low-volume runs.

LOW MOQ OF 300 m2.

SHIPS IN 10 DAYS OR LESS.

Our custom rollstock can be produced using any of our high-barrier films and is compatible with vertical and horizontal FFS lines, flow wrappers, and stick pack formers. Ask about free test rolls for new projects!

- Fully Custom Printed

- Choose Your Features

- High Barrier Films

- Safe for Food Contact

- Functional Prototypes