Stand Up Pouches

The Custom Printed Stand Up Pouch, our best selling product, is a versatile packaging solution that can hold nearly any consumer product you can think of. Stand Up Bags feature a bottom gusset that allows your product to stand up and stand out from the competition.

Bring your packaging to life with the following features:

Custom Printing

Custom Sizing

Custom Materials

Custom External Finish

Tear Notch

Window Knockouts

Metallic Effects

Hang Holes & Handles

Zip Closure

Degas Valve

Rounded Corners

Pour Spout

Custom Shape

Custom Printing

Using the world’s most advanced print technologies, you have full control on exactly how your pouches are printed from vector to photographic art elements.

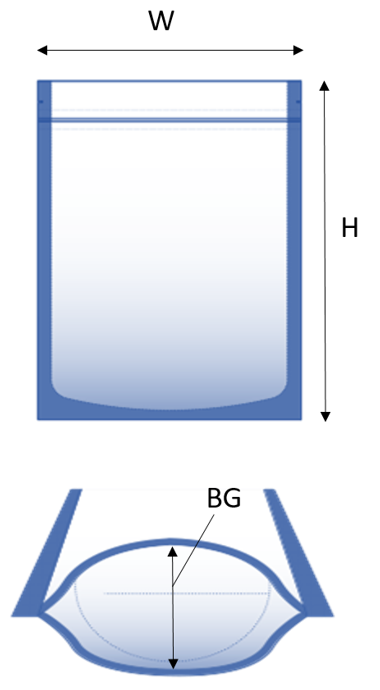

Custom Sizing

Fully customizable width, height, and bottom gusset – no size is off the table.

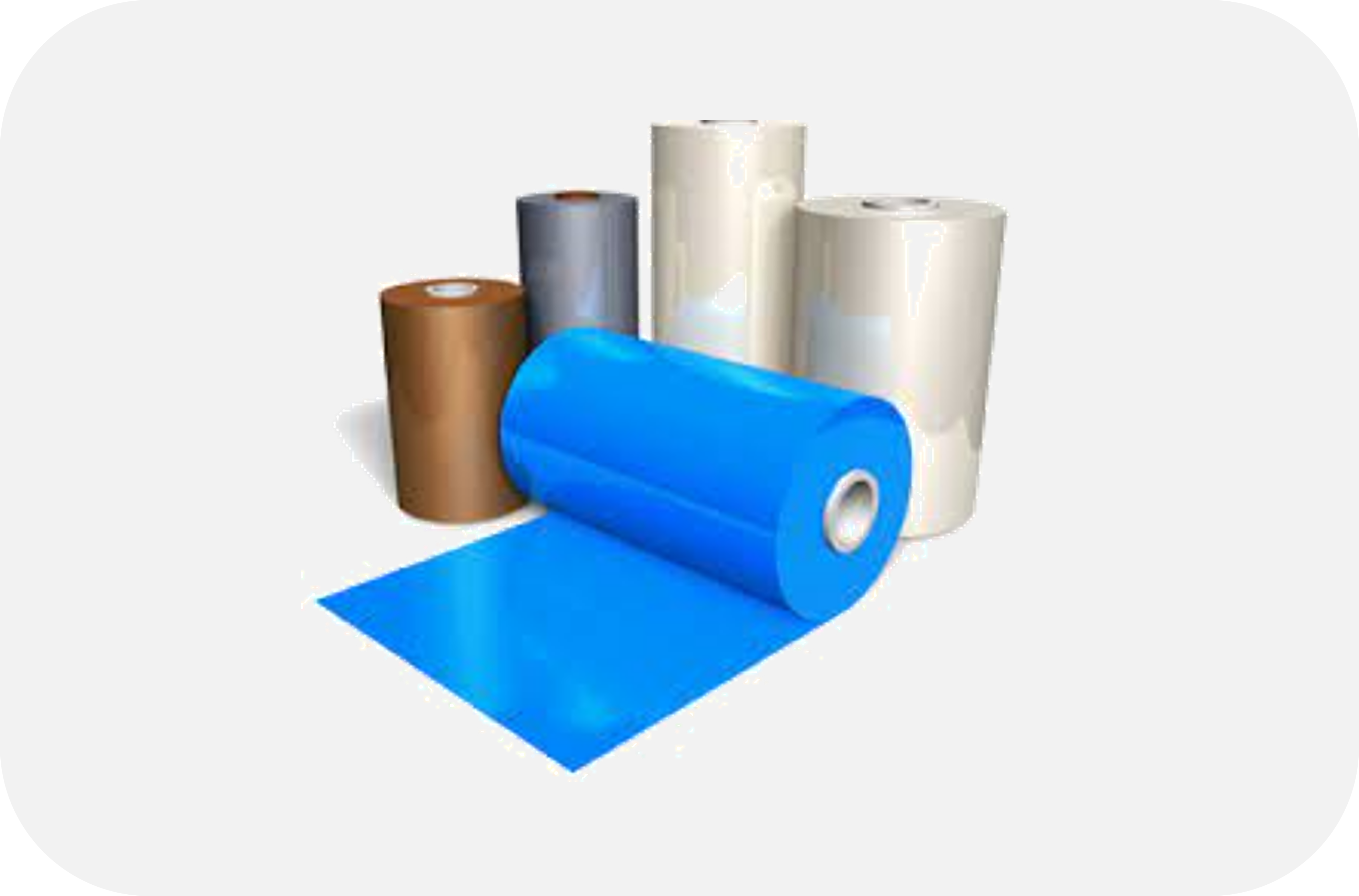

Custom Materials

Choose from a variety of high barrier films to protect your product such as PET, BOPP, Metalized PET, Aluminum Foil, and Kraft Paper

Custom External Finish

Choose from gloss, matte, or soft touch matte to complete your look.

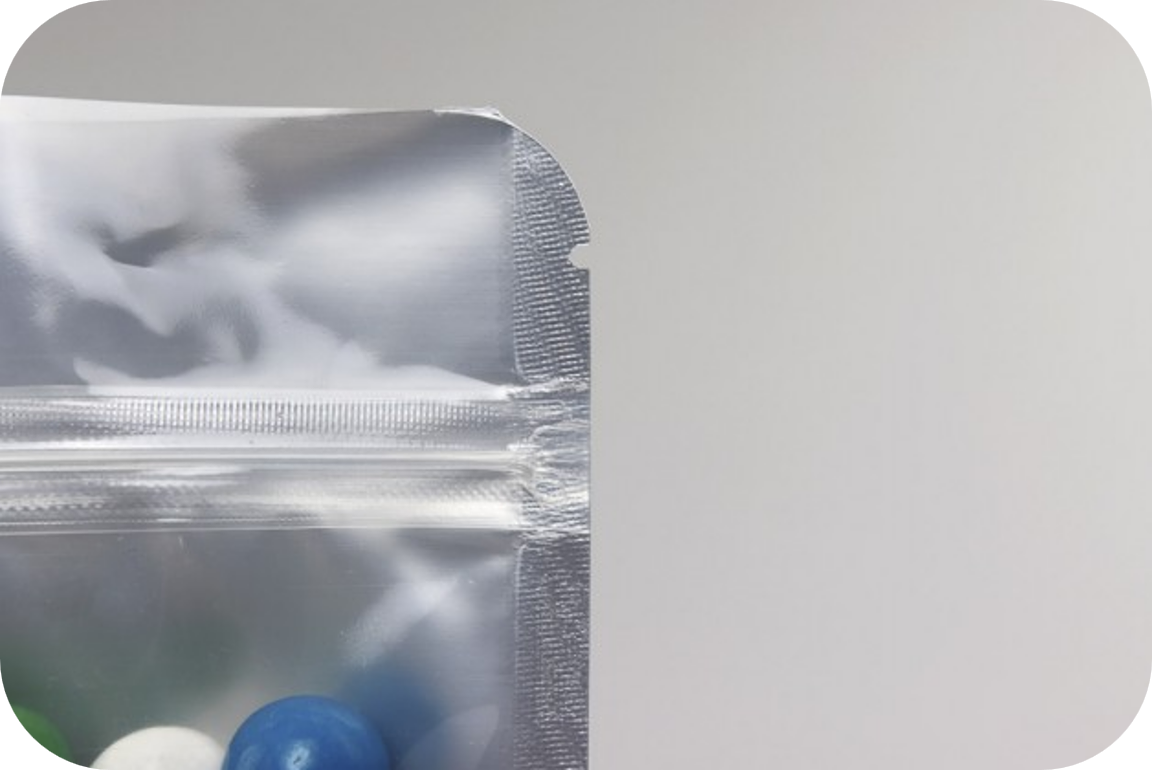

Tear Notch

Provide your customers an easy way to open their packaging.

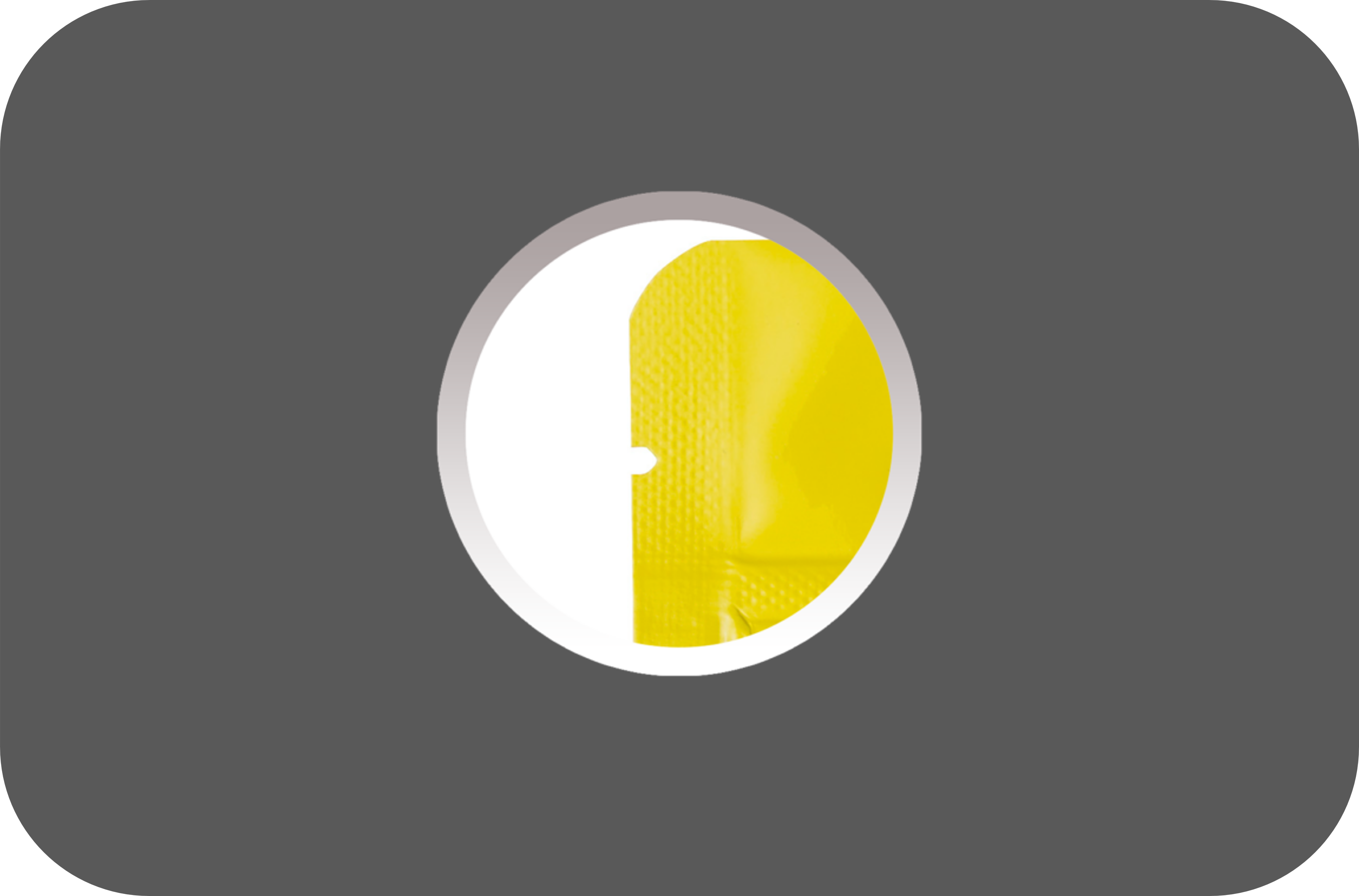

Window Knockouts

Give consumers a glimpse of your product by incorporating either clear or frosted windows throughout your design.

Metallic Effects

Make your graphics pop with metallic shine effects on your bag, anywhere and in any color.

Hang Holes & Handles

Opt for a round, sombrero, or custom handle tailored for your pouch.

Zip Closure

Keep your product fresh for longer by allowing customers to seal oxygen and moisture out of your bag.

Degas Valve

Protect your coffee beans or other gas producing product by using a one-way de-gas valve in your bag.

Rounded Corners

Don’t want the straight cut look? Rounded corners can change the game.

Pour Spout

Have product that you’d like to be able to pour from the pouch? No problem.

Custom Shape

Quality Assurance

Every pouch goes through a strict Quality Control process, ensuring the highest quality on every run.

Certified Production

Our manufacturing facilities are BRC-GS certified, the highest level for Food Packaging Safety.

High-Barrier Films

We only use films and materials that are recognized by the FDA as food contact safe. All inks are water based.

Low MOQ of 1000 bags.

Typically SHIPS IN 10 DAYS OR LESS.

Whether you are packaging your product for the first time or are a seasoned player, our stand up pouches are a safe, cost-effective, and quality choice. Choose between a round, K-corner, or plow bottom gusset. Print on the front, back, and bottom to show off your brand!

- Fully Custom Printed

- Choose Your Features

- High Barrier Films

- Safe for Food Contact

- Functional Prototypes